Carrinho de compras

Automação PLC | PLCs, quadros de distribuição (EN)

Conheça neste catálogo os componentes de automação ABB que lhe permitem responder a todas as aplicações, nomeadamente, infraestrutura de edifícios, águas, energias renováveis, data centers, etc.

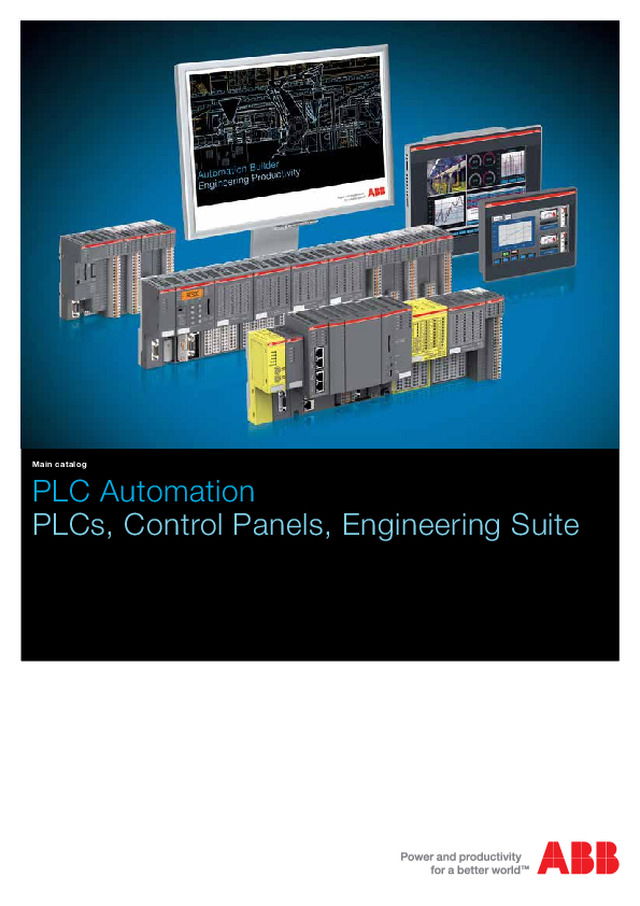

PLC Automation PLCs, Control Panels, Engineering Suite Main catalog

ABB PLC Automation | 1/1 PLC Automation PLCs, Control Panels, Engineering Suite PLC Automation product family Automation Builder - Integrated engineering suite AC500-eCo - Entry level PLC solutions AC500 - High performance modular PLC AC500-XC - PLC operating in eXtreme Conditions AC500-S - Functional Safety PLC CP600-eCo and CP600 control panels Application descriptions and additional information Index 3ADR020077C0203 - Edition December 2015 1 2 3 4 5 6 7 8 9

1/2 | ABB PLC Automation Comprehensive range ABB delivers scalable, flexible and efficient ranges of automation components to fulfill all conceivable automation applications. ABB's automation devices deliver solutions with high performance and flexibility to be effectively deployed within diverse industries and applications including water, building infrastructure, data centers, renewable energy, machinery automation, material handling, marine and more. Engineering suite ABB Automation Builder is the integrated software suite for machine builders and system integrators wanting to automate their machines and systems in a productive way. Combining the tools required for configuring, programming, debugging and maintaining automation projects from a common intuitive interface, Automation Builder addresses the largest single cost element of most of today's industrial automation projects: software. Programmable Logic Controllers PLCs The AC500, AC500eCo, AC500S and AC500XC scalable PLC ranges provide solutions for small, middle and highend applications. Our AC500 platform offers different performance levels and is the ideal choice for high availability, extreme environments or safety solutions. Our AC500 PLC platform offers interoperability and compatibility in hardware and software from compact PLCs up to high end and safety PLCs. Control panels The CP600eCo and CP600 HMI control panels offer a wide range of features and functionalities for maximum operability. ABB control panels are distinguished by their robustness and easy usability, providing all the relevant information from production plants and machines at a single touch. ABB offers a comprehensive range of scalable PLCs and robust HMI control panels as well as highavailability solutions. Since its launch in 2006, the AC500 PLC platform has achieved significant industry recognition for delivering high performance, quality and reliability. PLC Automation product family Overview 1

ABB PLC Automation | 1/3 Automation Builder Automation Builder integrates engineering and maintenance for PLC, Drives, Motion, HMI and Robotics. Automation Builder complies with the IEC 611313 standard offering all 5 IEC programming languages for PLC and drive configuration. In addition, Automation Builder includes continuous function chart, C/C++, extensive function block libraries and powerful embedded simulation and visualization features. Automation Builder supports various languages (English, German, French, Chinese, Spanish) and comes with new libraries, FTP functions, SMTP, SNTP, smart diagnostics and debugging capabilities. Download Automation Builder from www.abb.com/automationbuilder. AC500-eCo This compact PLC offers flexible and economical configurations for your modern control system. The ideal choice for smaller applications. AC500 Our powerful flagship PLC with a wide range of performance, communications and I/O capabilities for industrial applications. The ideal choice for complex high speed machinery and networking solutions. AC500-XC Extreme Condition PLC variant of the AC500 platform with extended operating temperature, immunity to vibration and hazardous gases, use at high altitudes and in humid conditions. AC500-S This safety PLC (SIL3, PL e) is designed for safety applications involved in factory or machinery automation area. The ideal choice to implement and manage complex safety solutions. CP600-eCo The economic control panel series offers touch screen graphic displays from 4.3" up to 10.1". The userfriendly configuration software PB610B Panel Builder 600 Basic provides the most commonly used HMI functions. Comprehensive sets of graphic symbols are available to support the design of tailormade HMI solutions. CP600 This control panel series offers a wide range of touch screen graphic displays from 4.3" up to 15". The userfriendly configuration software PB610 Panel Builder 600 provides stateoftheart HMI functions. Comprehensive sets of graphic symbols are available to support the design of tailormade HMI solutions. CP600WEB panels are available for the visualization of HMI applications provided by the AC500 WebServer. They include the Microbrowser instead of an HMI application. 1

1/4 | ABB PLC Automation PLC Automation product family Automation Builder Engineering Productivity for Machine Builders and System Integrators Product license options Automation Builder Basic Automation Builder Standard Automation Builder Premium Free n AC500eCo n n n AC500 with local I/O & network (1) n n n AC500 with fieldbus (2) n n AC500S Safety Drive Manager n n Drive application programming (3) Motion programming n (4) n n Panel Builder 600 n n Panel Builder 600 Basic n n n Integrated engineering (5) n n Productivity features (6) n Additional features (7) (1) TCP protocols, Modbus, IEC608705104, CS31(2) PROFIBUS, PROFINET, EtherCAT, CAN(3) Drive composer pro license needs to be purchased(4) No Fieldbus connectivity in Automation Builder Basic(5) PLC, Safety, Panel, Drive, Motion, Robotics(6) C/C++, ECAD data exchange, CSV interface extensions, project compare(7) Project Version Control 1

ABB PLC Automation | 1/5 Discover engineering productivity when engineering your discrete automation solutions. Automation Builder is ABB's integrated programming, maintenance and simulation environment for PLCs, safety, robots, motion, drives and control panels. Automation Builder combines the proven ABB tools RobotStudio, Drive Manager, Mint WorkBench, Panel Builder and succeeds Control Builder Plus. The Automation Builder minimizes your efforts for project code and data administration. Improve your productivity with seamless engineering, common data storage, a single project archive, timesaving library blocks for device integration, and one common software installer. Reduce engineering efforts and maintenance costs using easytouse libraries for wind, water, solar, drives, motion, robotics and safety applications. Benefit from the simplicity of IEC 611313, PLCopen, C/ C++, RAPID and MINT programming languages. Speed up your project with the powerful ECAD and MS EXCEL ® interfaces of Automation Builder. Simplified diagnostics and maintenance reduce downtime. Automation Builder is the perfect software suite for the configuration and programming of various ABB controller families in one single project. Safe and restore your applications with a consistent joint backup. Download Automation Builder from www.abb.com/automationbuilder. Familiarize with Automation Builder using a 30 days test license. After having tried and tested with your individual applications, you can use the free Automation Builder Basic or purchase the Automation Builder Standard or Premium. Streamline and simplify your engineering process: Reduce risk and save time. Risk Commissioning Risk Control Risk Electrical Mechanical Electrical Control Commissioning Mechanical Saved time Reduced risk 1

1/6 | ABB PLC Automation PLC Automation product family AC500 libraries A good investment for system integrators and endusers, AC500 libraries improve stability while reducing warranty costs and service. Library packages contain easytouse examples for minimal programming effort and quick implementation of complex and demanding applications. 1

ABB PLC Automation | 1/7 AC500 libraries deliver the seamless integration of drives, HMI and supervisory systems for the quick and easy building and commissioning of automation solutions. AC500 solution libraries by ABB are maintained to ensure that your programs can also be used with less risk. Motion control library Library package for decentral, central and coordinated motionaccording to the PLCopen ® standard. Solar library Library package for solar trackers increasing energy efficiency, providing quick commissioning and excellent positioning accuracy. Solar library Motion control library 1 2 3 Water library Water library Library package with energy efficiency functionalities offering quick commissioning of water applications, such as pump stations with remote communication. Drive integration library Library package for the quick integration of ABB ACS drives using different fieldbusses – freeofcharge included in Automation Builder. Temperature control library Library package for the advanced PID temperature control of demanding applications, for example extrusion. 4 Temperature control library 1

1/8 | ABB PLC Automation PLC Automation product family PLCs at a glance… AC500 Programmable Logic Controllers with scalable, stateoftheart technology for better performance. Standard industrial communication fieldbus, network and protocols supported by the 'One Platform' solution make the AC500 the perfect automation solution in even the most demanding environments. Flexible and scalable superior CPUs deliver performance whenever and wherever you need it. Ethernet enabled Fieldbus enabled Ethernet, Fieldbus and High Availability enabled Ethernet, Fieldbus, High Availability and enlarged memory eXtreme Conditions version available Functionality AC500-eCo AC500 CPU Performance PM554PM564 PM554ETHPM564ETH PM592ETH PM556ETHPM566ETH PM572 PM573ETH PM582 SM560SSafety CPU PM583ETH PM590ETHPM591ETHPM5912ETH Ethernet Fieldbus Ethernet and Fieldbus PM5954ETHF Ethernet and Fieldbus PM585ETH 1

ABB PLC Automation | 1/9 PLC Automation product family PLCs at a glance... AC500-eCo AC500 AC500-XC AC500-S (2) AC500-S-XC (2) System Configuration and Application programming Automation Builder (common programming tool) n n n n n Application Features Extended temperature range n n Functional safety n n Support of simple motion with FM562 module (1) n n n n n Support of coordinated motion (1) n n n n Support of High Availability (HA) n n CPU Features AC500-eCo AC500 AC500-XC AC500-S (2) AC500-S-XC (2) Performance (time per binary instruction) 0.08 µs 0.0006…0.06 µs 0.0006…0.06 µs 0.05 µs 0.05 µs Program memory 128...512 kB 128…16 MB 128…16 MB 1024 kB 1024 kB User data memory 14...130 kB 128…16 MB 128…16 MB 1024 kB 1024 kB Remanent data (= saved) 2 kB 12…3 MB 12…3 MB 120 kB 120 kB Serial communication RS232 n n n n RS485 n n n n n Isolated interface n n n n Ethernet features on CPU with integrated Ethernet or external communication module Online access (Programming) n n n n n ICMP (Ping), DHCP, IP configuration protocol n n n n n UDP data exchange, Modbus TCP n n n n n Ethernet features on CPU with integrated Ethernet only HTTP (integrated web server) n n n n n SNTP (Time synchronization) n n n n n FTP server n n n n n SMTP client (Simple Mail Transfer Protocol) n n n n IEC 608705104 remote control protocol n n n n Socket programming n n n n Downloadable protocol n n Capability to connect Fieldbus Modules n n n n I/Os integrated on CPU n I/O Modules Features S500-eCo S500 S500-XC S500-S (2) S500-S-XC (2) Analog modules Configurable n n Dedicated n n n Digital modules Configurable n n Dedicated n n n n n Transistor outputs short circuit protected n n n n Output diagnosis n n n n Extension with S500-eCo and S500(-XC) I/O modules n n n n (2) n (2) n fully partly (1) Requires Library PS552MCE.(2) AC500S and AC500SXC are extension CPU modules. They require an AC500 or AC500XC CPU to operate. The latter supports all communication interfaces. 1

1/10 | ABB PLC Automation 1 2 3 AC500-eCo central processing unit (CPU) – Different memory options – Integrated communication option. S500-eCo I/O modules – Up to 10 expansions – Decentralized extension available. 1 2 Terminal blocks – Three types of pluggable terminal blocks available. 3 PLC Automation product family AC500eCo 1

ABB PLC Automation | 1/11 Terminal base – Common for all AC500 CPU types – For 1, 2 or 4 communication modules – With serial interfaces. – With 1 or 2 Ethernet interfaces Communication modules – For PROFIBUS DP ® , Ethernet, Modbus TCP, EtherCAT ® CANopen ® , PROFINET ® IO or serial programmable – Up to 4 pluggable. AC500 central processing unit (CPU) – Different performance, memory, network, operating conditions options – Integrated communication. 1 3 2 1 3 2 4 5 S500 I/O modules – Up to 10 expansions – Decentralized extension available. Terminal units – Up to 10 terminal units – Decentralized extension available. 4 5 PLC Automation product family AC500 and AC500XC 1

1/12 | ABB PLC Automation PLC Automation product family AC500eCo system characteristics Locally, AC500eCo CPUs are expandable with up to 10 I/O modules. AC500eCo CPUs with different performance levels are available. 6 5 7 4 3 9 2 11 8 10 1 1

ABB PLC Automation | 1/13 Adapter with realtime clock AC500-eCo CPUs are locally expandable with up to 10 I/O modules (standard S500 and S500-eCo I/O modules can be mixed). Wall mounting SD-card adapter RS485 isolator for COM1 COM1 USB COM2 USB programming cable 1 2 SD-card Adapter with COM2 & realtime clock Adapter with COM2 Terminal blocks 3 4 5 6 7 8 9 10 11 AC500-eCo Starter kit. For more information, see page 149 1

1/14 | ABB PLC Automation 3 7 6 4 PLC Automation product family AC500 system characteristics AC500 offers superior local extension capabilities for I/O communication, bestinclass CPU functionality and industryleading performance. 8 2 5 9 1 1

ABB PLC Automation | 1/15 AC500 CPUs are locally expandable with up to 10 I/O modules (standard S500 and S500-eCo I/O modules can be mixed). 1 CPU module Communication module Up to 4 modules for multiple combinations to communicate with nearly everything 4 3 S500-eCo I/O module S500 I/O module S500 Terminal unit 5 6 7 Battery SD-card 8 9 Pluggable marker holder for I/O modules with template 10 Terminal base 2 1

1/16 | ABB PLC Automation PLC Automation product family AC500 PM595 Controller system characteristics The flagship of the AC500 platform, the AC500 PM595 Controller, was designed as scalable, flexible and efficient as the entire AC500 range. With the AC500 CPU PM595, ABB launched a new core for machine control applications. Its highperformance processor with generous memory offers performance, security and reliability for the upcoming challenges of automation applications. A variety of connectivity capabilities, integrated safety and utilizability even under rough environment provide machine builders with valuable benefits when performing their automation tasks. 3 5 2 6 4 1 1

ABB PLC Automation | 1/17 CPU with integrated connectivity and terminal base 2 S500-eCo I/O module S500 I/O module Communication module Up to 2 modules for multiple combinations to communicate with nearly everything 3 5 5 Battery SD-card 6 7 AC500 CPUs are locally expandable with up to 10 I/O modules (standard S500 and S500-eCo I/O modules can be mixed). 1 S500 Terminal unit 4 Pluggable marker holder for I/O modules with template 8 1

1/18 | ABB PLC Automation PLC Automation product family Condition monitoring system CMS based on AC500 Predictable performance for your operations Optimize your assets with a condition monitoring system (CMS) based on the proven AC500 platform. The new FM502 module can help you to improve your operations resulting in greater efficiency and higher reliability while minimizing service and operating costs. 1

ABB PLC Automation | 1/19 Add predictable performance and productivity The new CMS module brings further reliability and easy integration with all kinds of machinery systems, enabling precise management of the realtime condition of your operation. This transparency takes your business and productivity to a new level with more efficient machines, predictable performance and significant reduction in maintenance costs. No matter whether as standalone condition monitoring or integrated into machine or process control, the module is perfectly suited to build optimized, selfanalyzing automation solutions that simultaneously perform condition monitoring, control, protection, safety and data logger functions with one controller. The fast data logger function also contributes to consistent high quality production, due to the possibility to combine control and production information directly. CMS also protects against machine failures, unforeseen sudden damage, incorrect installation, and reduces maintenance and wear. Virtually no unscheduled downtimes boost plant availability and reliability. Advantages – Planned maintenance rather than spontaneous repair ensures predictable performance – Approaching damage is identified very early – Protection against spontaneous failures and operation in critical conditions – Reduction of costs in maintenance and lost production time – Plant availability is increased – Optimum utilization of the aggregates until real end of life – Simple to use, maintain, adapt or expand AC500 + CMS = increased machine efficiency All based on the AC500 platform modularity provides ultimate flexibility: Communication and I/O modules can be added and combined with Safety. Expandable, robust and proven – Standalone CMS or control integrated – Expandable by AC500 communication modules and AC500 I/O modules – Proven and future proof, as based on AC500 platform – Extreme conditions XC version available – Fast data logger, e. g. for production quality – Fast protection in parallel to condition monitoring Terminal base: TF501 or TF521 Accomodating: 0 or 2 communication modules PM592 CPU FM502 CMS module Expandable by I/O terminal units Expandable by further I/O modules Diagnostic PreWarning RMS Alarm Simple Analysis Warning Grad C OFF Very low V ibrations V ibrations Noise Heat Diagnostic V alue – KPI Time Months before Weeks before Days before Smoke 1 6 5 2 3 4 1 6 5 2 3 4 1

1/20 | ABB PLC Automation PLC Automation product family Extreme conditions PLC AC500XC – the rugged variant of AC500 for extreme indoor and outdoor conditions. The PLC AC500XC is reliable, functionally safe and operational even under rough environmental conditions. 1 2 3 1

ABB PLC Automation | 1/21 Operation in extremely humid environments – Increased resistance against 100 % humidity and condensation. Reliable in high altitudes – Operation in altitudes up to 4000 m above sea level or air pressures up to 620 hPa. Extended immunity to vibration – 4 g rms random vibration up to 500 Hz – 2 g sinusoidal vibration up to 500 Hz. Extended operating temperature – 40 °C up to +70 °C operating temperature. Extended immunity to corrosive gases and salt mist – G3, 3C2 immunity – Salt mist EN 60068252 / EN 60068211. Extended EMC requirements – EN 6100045 surge immunity test – EN 6100044 transient / burst immunity test. Extreme conditions S500 I/O module 6 4 Extreme conditions S500 terminal unit Extreme conditions CPU with integrated connectivity and terminal base 4 Extreme conditions CPU Extreme conditions communication module 2 3 5 Terminal base 1 1

1/22 | ABB PLC Automation PLC Automation product family Functional Safety AC500S Safety PLC is the solution for complex machine safety applications requiring maximum reliability, efficiency and flexibility. 1 3 2 This safety PLC protects people, machines and processes, the environment and investments the ideal choice for wind turbine, crane, hoist and robot applications. 1

ABB PLC Automation | 1/23 Better integration and ease of programming Featuring a consistent look and feel across the entire range, the AC500 is the PLC of choice for applications where uncompromised flexibility, comprehensive integration and seamless communication are a must. Automation Builder seamlessly integrates your safety application in ABB PLC, Safety, Drives, Motion, HMI and Robotics. Through integrated standard languages, such as IEC 611313, Automation Builder is easy to use thus allowing you to get started in virtually no time at all. And what is more: intuitive system configuration using one single tool ensures optimal transparency. Safety CPU 1 S500 Safety I/O module 2 3 Safety terminal unit 3 The AC500S Safety PLC, ABB's latest addition to the AC500 family, facilitates the implementation of even most complex safety applications. Support of safetyrelevant calculations, such as COS, SIN, TAN, ASIN, ACOS and LOG makes the AC500S the ideal solution for crane engineering, wind power generation, robotics and hoisting applications. Safety programming with Structured Text (ST) and full support for Function Block Diagram (FBD) and Ladder Diagram (LD) programming gives you greater flexibility and simplifies safety application development. The AC500S Safety PLC is also available in a version for extreme conditions. 1

1/24 | ABB PLC Automation PLC Automation product family CP600eCo and CP600 control panels With comprehensive but easytouse functionalities, ABB control panels stand out from competitor products. At one single touch, they intuitively provide operators with tailormade operational information for production plants and machines. CP600eCo / CP600 control panels make machine operation efficient, predictable and userfriendly. 1

ABB PLC Automation | 1/25 CP600-WEB with visualization for AC500 web server Automation Builder programming station Save engineering time by using Automation Builder for both your PLC and WebVisu Connectivity with Drives directly without PLC Build effective graphic interfaces with Panel Builder 600 - efficient representation of your information CP600-eCo / CP600 Automation Builder programming station AC500 without web server AC500 with web server Automation Builder programming station CP600-eCo / CP600 Drives 1

1/26 | ABB PLC Automation PLC Automation product family PLC Automation website – online tools The www.abb.com/plc website is a mine of information on our products and documentation. 3 2 4 1 5 6 7 1

ABB PLC Automation | 1/27 Programmable Logic Controllers PLCs – AC500-eCo (CPUs, S500-eCo I/O modules, Accessories) – AC500 (CPUs, Communication modules, Communication interface modules, S500 I/O modules, Accessories, Condition Monitoring CMS) – AC500-XC (CPUs, Communication modules, Communication interface modules, S500 I/O modules, Accessories, Condition Monitoring CMS) – AC500-S (CPUs, S500 I/O modules) Automation Builder engineering suite – Download link www.abb.com/automationbuilder Control panels – CP400 (Devices, Software, Accessories) – CP600-eCo (Devices, Software, Accessories) – CP600 (Devices, Software, Accessories) Legacy products – AC31 and previous series – CP500 – Wireless products 3 5 2 6 4 1 Highlights – Latest product news – Main catalog – YouTube Industries and applications Services – Documents and Downloads – Application examples (for Automation Builder programming) – FAQs – Training locations and courses – Business Online (spare parts) – Success Stories Related products (Drives, Drives channel network, Motion control, Robotics) Contact information for your country 7 8 9 8 9 1

2/28 | ABB PLC Automation 2

ABB PLC Automation | 2/29 Automation Builder Integrated engineering suite Key features 2/30 Ordering data 2/31 Software features 2/32 Libraries features 2/33 2

2/30 | ABB PLC Automation Automation Builder Key features Stay in control of your project:Automation Builder integrates engineering tools for PLCs, safety, robots, motion, drives and control panels. Reduce risk and save time:Automation Builder integrates products into solutions that create value for your customers. Connect to best in class tools:Automation Builder enables you to adapt the tool chain to your needs and workflows. Build your distinct solution:Automation Builder is open for your specific products and communication technology. Automation Builder Key features Download Automation Builder from www.abb.com/automationbuilder 2

ABB PLC Automation | 2/31 Automation Builder Ordering data Automation Builder Automation Builder Engineering Suite – Engineering Productivity and Maintenance for PLCs, safety, robots, motion, drives and control panels. – Supports IEC61131-3, CFC, C/ C++. Optional: MINT, Rapid for motion and robotics applications. – Language packs for English, German, Chinese, Spanish, French For Description Type Order code Price Weight(1 pce) kg Free 61131-3 engineering for simple PLC solutions (AC500 w/o fieldbus and safety) Automation Builder 1.x Basic Single (1) - - - Integrated Engineering for PLC, drives, motion, panels Automation Builder 1.x Standard Single (2) DM100-TOOL 1SAS010000R0101 0.005 Automation Builder 1.x Version Upgrade Single (2)(3) DM101-TOOL-UPGR 1SAS010001R0101 0.005 Integrated Engineering for PLC, drives, motion, panels and features for engineering productivity and collaboration Automation Builder 1.x Premium Single (2) DM102-PREM 1SAS010002R0101 0.005 Automation Builder 1.x Premium Upgrade Single (2)(4) DM103-PREM-UPGR 1SAS010003R0101 0.005 Automation Builder editions for a network of engineering PCs Automation Builder 1.x Standard Network (5) DM104-TOOL-NETW 1SAS010004R0101 0.005 Automation Builder 1.x Premium Network (5) DM105-PREM-NETW 1SAS010005R0101 0.005 Automation Builder 1.x Premium Upgrade Network (5)(6) DM106-PREM-UPGR-NETW 1SAS010006R0101 0.005 Project version control to support engineering teams and solutions Project Version Control for Automation Builder 1.x Single (2)(7) DM107-VCON 1SAS010007R0101 0.005 Project Version Control for Automation Builder 1.x Network (5)(7) DM108-VCON-NETW 1SAS010008R0101 0.005 Automation Builder licensing based on a USB Key USB Key for Automation Builder licenses (8) DM-KEY 1SAP193600R0001 0.010 (1) Free license (2) Single user license - bound to PC or DM-KEY (USB Key) (3) Purchase this option to upgrade Control Builder Plus to Automation Builder Standard Single (4) Purchase this option to upgrade Automation Builder Standard Single to Automation Builder Premium Single (5) Network license for shared usage within a local area network. Per license one user can use the license at the same time. (6) Purchase this option to upgrade Automation Builder Standard Network to Automation Builder Premium Network (7) Add-on to Automation Builder Standard or Premium edition. Automation Builder Standard / Premium must be purchased separately (8) Does not contain license. Automation Builder license must be purchased separately. Can carry an arbitrary number of licenses. Solar library Motion control library Water library Libraries For Description Type Order code Price Weight(1 pce) kg all AC500 CPUs Solar library (9) PS562-SOLAR 1SAP195000R0001 0.300 all AC500 CPUs Water library (10) PS563-WATER 1SAS030000R0101 0.300 all AC500 CPUs Motion Control library, Extended (9) PS552-MC-E 1SAP192100R0002 0.300 all AC500 CPUs Temperature control library (10) PS564-TEMPCTRL 1SAS030010R0101 0,010 (9) Delivery on USB stick that includes: library, single license code and documentation.(10) Delivery includes single user license - bound to PC or DM-KEY (USB Key), software can be downloaded. Further application libraries and examples: Please check and download further libraries and examples from: www.abb.com/plcUse English language setting, then click on "Application Examples".Application Examples explain functionality by using e.g. standard Automation Builder libraries and functions in simple examples. They are tested in the described example configuration and functionality only, they come with documentation and are free of charge.Applications Examples help to minimize valuable programming and testing time for specific applications. Temperature control library 2

2/32 | ABB PLC Automation Automation Builder Software features Automation Builder Basic Automation Builder Standard Automation Builder Premium Description Basic system engineering for FREE Integrated engineering of complex systems Productivity and Collaboration for System Integrators and Machine Builders Features - AC500-eCo, AC500 with local I/O, TCP/IP, Modbus, CS-31, IEC60870-5 - All 5 IEC 61131-3 languages IL, LD, FBD, SFC, ST, plus CFC - Drive application programming (IEC 61131-3) - Mint WorkBench for motion applications - RobotStudio Basic - PLC firmware update, download and online change to single or several PLCs - PLC simulation and debugging - Language packs available for EN, DE, ES, FR, CN Automation Builder Basic features plus - Integrated engineering for Panel, Drive, Motion, Robotics - AC500 PROFIBUS, PROFINET, EtherCAT, CAN, CMS - AC500 Safety (1) - Drive Manager Automation Builder Standard features plus - C/ C++ application programming interface - ECAD Interface AC500/ AC500-eCo for EPLAN P8 ® and Zuken E3 ® - Advanced CSV data exchange - Project compare Minimum PC requirements 1 GHz, 3 GB RAM, 10 GB free disk space Recommended Operating Systems Windows 7 32/64-bit, Windows 8.1 32/64-bit Target Systems - PLC AC500-eCo, AC500, AC500-XC, ACS880, DCT880 - Robot Controller IRC5 - NextMove motion controllers, MicroFlex and MotiFlex drives - AC500-S (1), - Control Panel CP600 and CP600-WEB Supported devices on PLC fieldbus - - All I/O and fieldbus modules for AC500 family - ACS355, ACS380, ACS580, ACS850, ACS880, ACQ810, DCT880, ACSM1, MicroFlex e150, Motiflex e180, IRC5 on selected fieldbuses Included components - IEC61131-3 Editor - PS553-DRIVES drive library - RobotStudio (Basic license) - Mint WorkBench - OPC server and clients, service tool, PLC gateway, IP configuration and visualization - PB610-B Automation Builder Basic plus - Drive Manager - Drive Composer pro license - Panel Builder 600 Automation Builder Standard plus - GNU compiler, C/ C++ programming (2) - ECAD interface for EPLAN P8 ® and Zuken E3 ® Additional options - RobotStudio Premium license - Panel Builder 600 license - Drive composer pro license - PS501-S safety library - PS541-HMI visualization - PS552-MC-E PLCopen ® motion library - Project Version Control - Project Version Control (1) requires PS501-S safety library. (2) for AC500 and AC500-XC targets. 2

ABB PLC Automation | 2/33 PS552-MC-E PS562-SOLAR PS563-WATER PS564-TEMPCTRL Motion control library Solar tracker solution library Water solution library Temperature Control Library Library enabling fast and stan dardized engineering according to PLCopen ® standard when using ABB's AC500 PLC for motion control, especially together with ABB's motion control Drives. Covers different motion control options for single and multiaxis motion control applications: – Drive-Based and PLC-Based motion – In PLC based motion, the position control loop could be closed in the PLC or drive (with synchronized network) – Single axis, multiaxis and coordinated motion – Defined Jerk limitation by polynomial interpolation – Spline interpolation or polynomial interpolation for cam curves, position velocity or acceleration profiles available – Possible to switch over between different movements and cam curves directly – latch functionality by utilizing fast drive inputs for ACS350, ACS800, ACSM1 – Drive based motion: commands from PLC, drives perform inter polation and control loop – Supports the new Pulse Train Output module FM562. PLCopen ® functions: – Administrative Function Blocks – Single axis Function Blocks – Multiple axis Function Blocks – Homing Function Blocks – Coordinated Motion Function Blocks – Additional ABB specific Function Blocks for further simplification. Library for solar tracking applications enabling fast engineering, especially together with ABB's drives and motors Covers different tracker configurations and different algorithms for accuracy needs – Control of trackers in parabolic trough, power tower, PV and CPV applications. Complete library package for different tracking use cases, plug and play:Example program with detailed explanations and visualizations – Control of the tracker adaptable to different needs and conditions, to achieve maximum efficiency of installation – Exact positioning of different axes with the following accuracies: - NOAA algorithm 0.03 Grad - NREL algorithm 0.0003 Grad. – Input / sensor adaptation – Communication – Different actuators / drives control – All needed modes for simple commissioning and manual operation: - Fast and simple calibration of the trackers, offering manual repo sitioning and fine tuning - Safety positions - Back tracking. Library supporting the most common functions in many water applications Flexible data logging options: – Especially suited for remote communication like GSM/GPRS – Timestamp in logging – Integrated variants for simple use with IEC 60870 – Logging to files: storage capacity only dependent on memory availability – Flexible log conditions (cyclic, event or tolerance based). Support for pumping station functions with different operation modes – Standard multidrive functions (PLC based) – Advanced functionality together with ABB ACS and ACQ810 drives – Detailed diagnosis – Energy efficiency functions – Multidrive functions – Flow estimation. Control Panel CP600 support for ACQ810: Fast and simple configuration for pumping stations with reduced programming effort via pre-built visualization screen templates. Application examples for fast engineering and startup. Library packet for advanced temperature control applications Includes extended, flexible PID functionality with Auto-tune for temperature control – Enhanced response time and reduced overshoots and oscillations – Option to optimize control for very different heating and cooling characteristics. – Enhanced tolerance to thermocouple input noise – Normal and standby- setpoints – Multi-level temperature monitoring and alarms provides flexible operation and protection for machine and process – Logging enables complete overview of the actual situation and past behavior – Configurable output timing, synchronization for peak load shaving in multi-zone setups – Simulation blocks enable off-line setup and pre-test of a new project – Group-programming Example projects, including adaptable HMI project for CP600 family, well suited for multi zone and grouped temperature control e.g. in Extrusion: – Easy to use operator interface – Provides quick access to setup, monitoring and tuning screens for multiple zones – Easily expandable to a large number of zones – Zones: heat-, cool-only or heat-and- cool Package with self installing software and license code on USB-stick. Package with self installing software and license code on USB-stick. License Package (Software is part of Automation Builder) License Package (Software is part of Automation Builder) All AC500 CPUs (options and no. of blocks/functions and performance will depend on CPU size and memory). NOAA: PM554-XX and above NREL: PM573-ETH and above. All AC500 CPUs. Logging: PM573 and above. All AC500 CPUs. Automation Builder Libraries features 2

3/34 | ABB PLC Automation 3

ABB PLC Automation | 3/35 AC500-eCo Entry level PLC solutions Key features 3/36 Ordering data 3/37 Technical data 3/40 System data 3/47 3

3/36 | ABB PLC Automation AC500-eCo Key features – Up to 10 I/O modules connected to the CPU – Compatible with all standard I/O modules (S500 and S500-eCo) – Digital I/O module with configurable I/O available High performance variant with large memory available Comprehensive communication options:– Ethernet for communication and web server for user defined visualization – Up to two serial ports for decentralized I/O and communication – Three different types of terminal blocks available – Integrated onboard I/O– AC versions with integrated power supply 3

ABB PLC Automation | 3/37 AC500-eCo CPUs – 1 RS485 serial interface (2nd is optional) – Centrally expandable with up to 10 I/O modules (standard S500 and/or S500-eCo modules can be mixed) – Optional SD card adapter for data storage and program backup – Variants with integrated Ethernet (Ethernet includes web server) – Minimum cycle time per instruction: Bit 0.08 µs, Word 0.1 µs, Float-point 1.2 µs. Program memory Onboard I/Os Relay /Transistor outputs Integrated communication Power supply Type Order code Price Weight(1 pce) kB DI/DO/AI/AO kg PM554: digital I/Os128 8 / 6 / – / – Transistor – 24 V DC PM554-TP 1SAP120600R0001 0.300 128 8 / 6 / – / – Relay – 24 V DC PM554-RP 1SAP120700R0001 0.400 128 8 / 6 / – / – Relay – 100-240 V AC PM554-RP-AC 1SAP120800R0001 0.400 128 8 / 6 / – / – Transistor Ethernet 24 V DC PM554-TP-ETH 1SAP120600R0071 0.400 PM556: digital I/Os, 512 kB program memory512 8 / 6 / – / – Transistor Ethernet 24 V DC PM556-TP-ETH 1SAP121200R0071 0.400 PM564: digital and analog I/Os (1)128 6 / 6 / 2 / 1 Transistor – 24 V DC PM564-TP 1SAP120900R0001 0.300 128 6 / 6 / 2 / 1 Relay – 24 V DC PM564-RP 1SAP121000R0001 0.400 128 6 / 6 / 2 / 1 Relay – 100-240 V AC PM564-RP-AC 1SAP121100R0001 0.400 128 6 / 6 / 2 / 1 Transistor Ethernet 24 V DC PM564-TP-ETH 1SAP120900R0071 0.300 128 6 / 6 / 2 / 1 Relay Ethernet 24 V DC PM564-RP-ETH 1SAP121000R0071 0.400 128 6 / 6 / 2 / 1 Relay Ethernet 100-240 V AC PM564-RP-ETH-AC 1SAP121100R0071 0.400 PM566: digital and analog I/Os, 512 kB program memory (1)512 6 / 6 / 2 / 1 Transistor Ethernet 24 V DC PM566-TP-ETH 1SAP121500R0071 0.400 Terminal blocks (9 and 11 poles) are necessary for each AC500-eCo I/O. The terminal blocks must be ordered separately.(1) All analog inputs on PM564 and PM566 can be configured as digital inputs. AC500-eCo Ordering data PM554 PM556 PM564 PM566 3

3/38 | ABB PLC Automation AC500-eCo Ordering data S500-eCo I/O modules – For central expansion of the AC500 or AC500-eCo CPUs – For decentralized expansion in combination with communication interface module DC551-CS31, PROFINET ® CI50x modules, CI592-CS31, PROFIBUS ® modules CI54x, and CANopen ® modules CI58x (not usable with DC505-FBP module and CI590-CS31-HA). Digital I/O – DC: Channels can be configured individually as inputs or outputs. Number of Input signal Output type Output signal Terminal block required Type Order code Price Weight(1 pce) DI/DO/DC 9 poles 11 poles kg 8 / – / – 24 V DC – – 1 – DI561 1TNE968902R2101 0.12 16 / – / – 24 V DC – – 1 1 DI562 1TNE968902R2102 0.12 8 / – / – 100-240 V AC – – 1 1 DI571 1TNE968902R2103 0.15 16 / – / – 100-240 V AC – – 1 1 DI572 1SAP230500R0000 0.19 – / 8 / – – Transistor 24 V DC, 0.5 A – 1 DO561 1TNE968902R2201 0.12 – / 16 / – – Transistor 24 V DC, 0.5 A 1 1 DO562 1SAP230900R0000 0.16 – / 8 / – – Relay 24 V DC, 120 / 240 V AC, 2 A – 1 DO571 1TNE968902R2202 0.15 – / 8 / – – Triac 100-240 V AC, 0.3 A 1 1 DO572 1TNE968902R2203 0.12 – / 16 / – – Relay 24 V DC, 120 / 240 V AC, 2 A 1 1 DO573 1SAP231300R0000 0.19 8 / 8/ – 24 V DC Transistor 24 V DC, 0.5 A 1 1 DX561 1TNE968902R2301 0.12 8 / 8/ – 24 V DC Relay 24 V DC, 120 / 240 V AC, 2 A 1 1 DX571 1TNE968902R2302 0.15 – / – / 16 24 V DC Transistor 24 V DC, 0.1A HE10-20 – DC561 1TNE968902R2001 0.12 – / – / 16 24 V DC Transistor 24 V DC, 0.5 A 1 1 DC562 1SAP231900R0000 0.15 Terminal blocks (9 or 11 poles) are necessary for each S500-eCo I/O. The terminal blocks must be ordered separately. Analog I/O – Each channel can be configured individually – Resolution: - AI561, AO561, AX561: 12 bits/11 bits + sign - AI562, AI563: 15 bits + sign. Number of Input signal Output signal Terminal block required Type Order code Price Weight(1 pce) AI/AO 9 poles 11 poles kg 4 / 0 ±2.5 V, ±5 V, 0...5 V, 0...10 V, 0...20 mA, 4...20 mA – 1 1 AI561 1TNE968902R1101 0.12 2 / 0 PT100, PT1000, Ni100, Ni1000, Resistance: 150 Ω, 300 Ω – – 1 AI562 1TNE968902R1102 0.12 4 / 0 S, T, R, E, N, K, J, Voltage range: ±80 mV – 1 1 AI563 1TNE968902R1103 0.12 0 / 2 – -10...+10 V, 0...20 mA, 4...20 mA – 1 AO561 1TNE968902R1201 0.12 4 / 2 ±2.5 V, ±5 V, 0...5 V, 0...10 V, 0...20 mA, 4...20 mA -10...+10 V, 0...20 mA, 4...20 mA 1 1 AX561 1TNE968902R1301 0.13 Terminal blocks (9 or 11 poles) are necessary for each S500-eCo I/O. The terminal blocks must be ordered separately. DI561 AI562 AX561 3

ABB PLC Automation | 3/39 AC500-eCo Ordering data Positioning module – For central expansion of the AC500 or AC500-eCo CPUs – For decentralized expansion in combination with communication interface modules CI50X-PNIO or CI54X-DP – The FM562 module provides Pulse Train Outputs for 2 axes. Profile generator integrated. Number of axis Input signal Output signal Terminal block required Type Order code Price Weight(1 pce) 9 poles 11 poles kg 2 4 digital inputs 24 V (2 per axis) 4 pulse outputs RS422 (2 per axis) 1 1 FM562 1SAP233100R0001 0.15 Terminal blocks (9 or 11 poles) are necessary for each S500-eCo I/O. The terminal blocks must be ordered separately. Library PS552-MC-E is required for programming this module. Accessories Description Type Order code Price Weight(1 pce) kg SD Memory Card 2 GB needs the MC503 option MC502 1SAP180100R0001 0.020 SD Memory Card adapter MC503 1TNE968901R0100 0.010 Programming cable USB = RS485 Sub-D, 3 m TK503 1TNE968901R1100 0.400 Programming cable USB = RS485 Terminal block, 3 m TK504 1TNE968901R2100 0.400 RS485 isolator, Sub-D 9 poles / Terminal 5 poles for COM1 TK506 1SAP186100R0001 0.080 Real time clock option board, battery CR2032 not included TA561-RTC (1) 1SAP181400R0001 0.007 RS485 serial adapter COM2, pluggable screw terminal block included TA562-RS 1TNE968901R4300 0.007 Combined Real Time Clock option with RS485 serial adapter COM2, pluggable screw terminal block, included TA562-RS-RTC (1) 1SAP181500R0001 0.012 Wall Mounting Accessory for AC500-eCo CPU and S500-eCo I/O modules (100 pieces per case) TA566 1TNE968901R3107 0.450 Set of accessories: 6 x plastic cover for option slot, 6 x 5 pole terminal block, 6 x 5 pole screw terminal block for COM2 serial interface. TA570 1TNE968901R3203 0.090 Digital input simulator for onboard I/O of CPU, 6 x switch, 24 V DC TA571-SIM 1TNE968903R0203 0.040 (1) Standard battery CR 2032 has to be purchased separately. Terminal blocks for S500-eCo I/O modules and AC500-eCo CPUs Number of poles Connection type Cable entry Type Order code Price Weight(1 pce) kg 9 Screw Side TA563-9 1TNE968901R3101 0.017 11 Screw Side TA563-11 1TNE968901R3102 0.020 9 Screw Front TA564-9 1TNE968901R3103 0.026 11 Screw Front TA564-11 1TNE968901R3104 0.035 9 Spring Front TA565-9 1TNE968901R3105 0.016 11 Spring Front TA565-11 1TNE968901R3106 0.020 Only ABB terminal blocks must be used with AC500-eCo. Sales package for these terminal blocks = 6. TA562-RS-RTC TA562-RS TA561-RTC TA570 FM562 TA565-9 TA564-11 TK506 TA563-9 3

3/40 | ABB PLC Automation AC500-eCo Technical data AC500-eCo CPUs Type PM554-TP PM554-RP PM554-RP-AC PM554-TP-ETH PM556-TP-ETH Supply voltage 24 V DC 100-240 V AC 24 V DC Current consumption on 24 V DC 100 V AC 240 V AC 24 V DC Min. typ. (module alone) 0.06 A 0.08 A 0.02 A 0.012 A 0.07 A 0.07 A Max. typ. (I/Os) 0.18 A 0.22 A 0.2 A 0.11 A 0.19 A 0.19 A Program memory 128 kB 512 kB Integrated data memory 14 kB thereof 2 kB saved 130 kB thereof 2 kB saved Web server's data for user RAM disk – 512 kB 1024 kB Data buffering (of saved data) flash memory Real-time clock (option with battery back-up) (1) Program execution Cyclical Time controlled Multi tasking no, 1 task + 1 interrupt task max. Interruption User program protection by password Cycle time for 1 instruction (minimum) Binary 0.08 µs Word 0.1 µs Floating 1.2 µs Onboard digital inputs Channels 8 (including 2 counter inputs) Signal voltage 24 V DC Onboard digital outputs Channels 6 (including 2 PWM outputs) Relay / Transistor Transistor Relay Relay Relay Transistor Transistor Rated voltage 24 V DC 240 V AC 240 V AC 240 V AC 24 V DC 24 V DC Nominal current per channel 0.5 A 2 A resistive 2 A resistive 2 A resistive 0.5 A 0.5 A Onboard analog outputs Channels - signal ranges - Onboard analog inputs Channels - signal ranges - Max. number of centralized inputs/outputs Max. number of extension modules on I/O bus up to max. 10 (S500 and/or S500-eCo modules allowed) Digital inputs 320 + 8 outputs 320 + 6 Analog inputs 160 outputs 160 Max. number of decentralized inputs/outputs I/O modules decentralized on CS31 bus: up to 31 stations with up to 120 DI / 120 DO each or up to 32 AI/32 AO per station Internal interfaces COM1 RS485 Sub-D connection Programming, Modbus, ASCII, CS31 COM2 (option) (2) RS485 Terminal block Programming, Modbus, ASCII Ethernet RJ45 – Ethernet functions: Programming, Modbus TCP/IP, UDP/IP, integrated Web server, DHCP, FTP server, SNTP client – SMTP – RUN/STOP switch LED display for power, status and error Approvals see detailed overview page 154 or www.abb.com/plc (1) Real-time clock requires optional TA561-RTC or TA562-RS-RTC.(2) COM2 requires TA562-RS-RTC or TA562-RS. 3

ABB PLC Automation | 3/41 AC500-eCo Technical data AC500-eCo CPUs Type PM564-TP PM564-RP PM564-RP-AC PM564-TP-ETH PM566-TP-ETH PM564-RP-ETH PM564-RP-ETH-AC Supply voltage 24 V DC 100-240 V AC 24 V DC 100-240 V AC Current consumption on 24 V DC 100 V AC 240 V AC 24 V DC 100 V AC 240 V AC Min. typ. (module alone) 0.095 A 0.11 A 0.02 A 0.011 A 0.10 A 0.10 A 0.12 A 0.023 A 0.014 A Max. typ. (I/Os) 0.21 A 0.24 A 0.21 A 0.125 A 0.22 A 0.22 A 0.25 A 0.22 A 0.13 A Program memory 128 kB 512 kB 128 kB 0.22 A 0.13 A Integrated data memory 14 kB thereof 2 kB saved 130 kB thereof 2 kB saved 14 kB thereof 2 kB saved Web server's data for user RAM disk 512 kB 1024 kB 512 kB Data buffering (of saved data) flash memory Real-time clock (option with battery back-up) (1) Program execution Cyclical Time controlled Multi tasking no, 1 task + 1 interrupt task max. Interruption User program protection by password Cycle time for 1 instruction (minimum) Binary 0.08 µs Word 0.1 µs Floating 1.2 µs Onboard digital inputs Channels 6 (including 2 counter inputs) Signal voltage 24 V DC Onboard digital outputs Channels 6 (including 2 PWM outputs) Relay / Transistor Transistor Relay Relay Transistor Transistor Relay Relay Rated voltage 24 V DC 240 V AC 240 V AC 24 V DC 24 V DC 240 V AC 240 V AC Nominal current per channel 0.5 A 2 A resistive 2 A resistive 0.5 A 0.5 A 2 A resistive 2 A resistive Onboard analog inputs Channels 2 signal ranges 0...10 V / can be configured as digital input 24 V DC Onboard analog outputs Channels 1 signal ranges 0...10 V / 0...20 mA / 4...20 mA Max. number of centralized inputs/outputs Max. number of extension modules on I/O bus up to max. 10 (S500 and/or S500-eCo modules allowed) Digital inputs 320 + 8 outputs 320 + 6 Analog inputs 160 + 2 outputs 160 + 1 Max. number of decentralized inputs/outputs I/O modules decentralized on CS31 bus: up to 31 stations with up to 120 DI / 120 DO each or up to 32 AI/32 AO per station Internal interfaces COM1 RS485 Sub-D connection Programming, Modbus, ASCII, CS31 COM2 (option) (2) RS485 Terminal block Programming, Modbus, ASCII Ethernet RJ45 – Ethernet functions: Programming, Modbus TCP/IP, UDP/IP, integrated Web server, DHCP, FTP server, SNTP client – SMTP RUN/STOP switch LED display for power, status and error Approvals see detailed overview page 154 or www.abb.com/plc (1) Real-time clock requires optional TA561-RTC or TA562-RS-RTC.(2) COM2 requires TA562-RS-RTC or TA562-RS. 3

3/42 | ABB PLC Automation AC500-eCo Technical data Digital S500-eCo I/O modules Type DI561 DI562 DI571 DI572 DO561 DO562 Supply voltage – – – – 24 V DC 24 V DC Current consumption on UP Max. typ. (without load current) – – – – 0.005 A 0.005 A Number of channels per module Digital inputs 8 16 8 (AC) 16 (AC) – – outputs – – – – 8 16 Configurable as Input or Output DC – – – – – – Relay / Transistor – – – – Transistor Transistor Additional configuration of channels as: Fast Counter no not applicable Digital inputs Input signal voltage 24 V DC 100-240 V AC – – Input time delay typically 4...8 ms typically 15 ms / 30 ms – – Input current per channel At Input voltage 24 V DC typically 5 mA – – – – 5 V DC typically 1 mA – – – – 15 V DC 2.5 mA – – – – 30 V DC 8 mA – – – – 40 V AC – – 3 mA – – 164 V AC – – 6 mA – – Output current Nominal current per channel – – – – 0.5 A at UP = 24 V Maximum (total current of all channels) – – – – 4 A 8 A Residual current at signal state 0 – – – – 0.5 mA Demagnetization when switching off inductive loads – – – – must be provided externally Switching frequency For resistive load – – – – limited by CPU cycle time For inductive load – – – – max. 0.5 Hz For lamp load – – – – max. 11 Hz at max. 5 W Short circuit / overload proofness – – – – no Overload indication (I 0.7 A) – – – – no Output current limiting – – – – no Proofness against reverse feeding of 24 V signals – – – – no Contact rating For resistive load, max. – – – – – – For inductive load, max. – – – – – – For lamp load – – – – – – Lifetime (switching cycles) Mechanical lifetime – – – – – – Lifetime under load – – – – – – Maximum cable length for connected process signals Cable shielded 500 m unshielded 300 m 150 m Potential isolation Per module Between the channels input – per group of 8 per group of 8 – – output – – – – – – Voltage supply for the module's logic internal via I/O bus Fieldbus connection Suitable communication interface module CI501-PNIO, CI502-PNIO, CI504-PNIO, CI506-PNIO, CI541-DP, CI542-DP, CI581-CN, CI582-CN, DC551-CS31, CI592-CS31 3

ABB PLC Automation | 3/43 AC500-eCo Technical data Digital S500-eCo I/O modules Type DO571 DO572 DO573 Supply voltage 24 V DC Current consumption on UP Max. typ. (without load current) 0.050 A – 0.050 A Number of channels per module Digital inputs – – – outputs 8 8 16 Configurable as Input or Output DC – – – Relay / Transistor Relay triac (AC) Relay Process voltage DC 24 V – – Digital inputs Input signal voltage – – – Input time delay – – – Input current per channel At Input voltage 24 V DC – – – 5 V DC – – – 15 V DC – – – 30 V DC – – – Output current Nominal current per channel 2 A (24 V DC / 120 V AC / 240 V AC, resistive load) 0.3 A at 100...240 V AC 2 A (24 V DC / 120 V AC / 240 V AC, resistive load) Maximum (total current of all channels) 2 x 8 A 2.4 A / 8 x 0.3 A max 10 A per group (20 A per module) Residual current at signal state 0 – 1.1 mA rms at 132 V AC and 1.8 mA rms at 264 V AC – Demagnetization when switching off inductive loads must be performed externally Switching frequency For resistive load 1 Hz max. 10 Hz max. 1 Hz max. For inductive load – – – For lamp load 1 Hz max. 10 Hz max. 1 Hz max. Short circuit / overload proofness no Overload indication (I 0.7 A) no Output current limiting no Proofness against reverse feeding of 24 V signals yes – yes Contact rating For resistive load, max. 2 A 0.3 A 2 A For inductive load, max. – – – For lamp load 200 W at 230 V AC 30 W at 24 V DC – 200 W at 230 V AC 30 W at 24 V DC Lifetime (switching cycles) Mechanical lifetime 100 000 – 100 000 Lifetime under load 100 000 at rated load – 100 000 at rated load Maximum cable length for connected process signals Cable shielded 500 m unshielded 150 m Potential isolation Per module between outputs and logic between outputs and logic Between the channels input – – – output per group of 4 per group of 8 Voltage supply for the module's logic internal via I/O bus Fieldbus connection Suitable communication interface module CI501-PNIO, CI502-PNIO, CI504-PNIO, CI506-PNIO, CI541-DP, CI542-DP, CI581-CN, CI582-CN, DC551-CS31, CI592-CS31 3

3/44 | ABB PLC Automation AC500-eCo Technical data Digital S500-eCo I/O modules Type DX561 DX571 DC561 DC562 Supply voltage 24 V DC Current consumption on UP Max. typ. (without load current) 0.005 A 0.050 A 0.010 A 0.010 A Number of channels per module Digital inputs 8 8 – – outputs 8 8 – – Configurable as Input or Output DC – – 16 16 Relays / Transistor Transistor Relay Transistor Transistor Process voltage DC 24 V 24 V 24 V 24 V Digital inputs Input signal voltage 24 V DC 24 V DC 24 V DC 24 V DC Input time delay typically 4...8 ms typically 8 ms Input current per channel At Input voltage 24 V DC typically 5 mA typically 5 mA typically 4 mA typically 5 mA 5 V DC 1 mA 1 mA 1 mA typically 1 mA 15 V DC 2.5 mA 2.5 mA 2.5 mA 2.5 mA 30 V DC 6.5 mA 6.5 mA 6 mA 8 mA Output current Nominal current per channel 0.5 A at UP = 24 V DC 2 A (24 V DC / 120 V AC / 240 V AC, resistive load) 0.1 A at UP = 24 V DC 0.5 A at UP = 24 V DC Maximum (total current of all channels) 4 A 2 x 8 A 1.6 A 8 A Residual current at signal state 0 0.5 mA – 0.5 mA 0.5 mA Demagnetization when switching off inductive loads must be performed externally Switching frequency For resistive load Limited by CPU cycle time 1Hz max. Limited by CPU cycle time For inductive load 0.5 Hz max. – 0.5 Hz max. 0.5 Hz max. For lamp load 11 Hz max. at max. 5 W 1 Hz max. – 11 Hz max. at max. 5 W Short circuit / overload proofness no Overload indication (I 0.7 A) no Output current limiting no Proofness against reverse feeding of 24 V signals no yes no no Contact rating For resistive load, max. – 2 A – – For inductive load, max. – – – – For lamp load – 200 W at 230 V AC 30 W at 24 V DC – – Lifetime (switching cycles) Mechanical lifetime – 100 000 – – Lifetime under load – 100 000 at rated load – – Maximum cable length for connected process signals Cable shielded 500 m unshielded 150 m Potential isolation Per module – Between the channels input – – – – output – per group of 4 – – Voltage supply for the module's logic internal via I/O bus Fieldbus connection Suitable communication interface module CI501-PNIO, CI502-PNIO, CI504-PNIO, CI506-PNIO, CI541-DP, CI542-DP, CI581-CN, CI582-CN, DC551-CS31, CI592-CS31 3

ABB PLC Automation | 3/45 AC500-eCo Technical data Analog S500-eCo I/O modules Type AI561 AO561 AX561 AI562 AI563 Supply voltage 24 V DC Current consumption on UP Max. typ. (without load current) 0.100 A 0.100 A 0.140 A 0.040 A 0.100 A Number of channels per module Analog inputs 4 – 4 2 4 outputs – 2 2 – – Inputs, individually configurable -2.5…+2.5 V 11 bits + sign – – – -5…+5 V 11 bits + sign – – – -10…+10 V 11 bits + sign – – – – – 0…5 V 12 bits – – – 0…10 V 12 bits – – – 0…20 mA, 4…20 mA 12 bits – – – RTD – – – 2 – Pt100 -50…+400 °C (2/3- wire) – – – – Pt1000 -50…+400 °C (2/3-wire) – – – – Ni100 / Ni1000 -50…+150 °C (2/3-wire) – – – – Resistor 0…150 Ω/0...300 Ω – – – – Thermocouple Types J, K, T, N, S, E, R – – – – Voltage -80...+80 mV – – – – Outputs, individually configurable -10...+10 V – – – 0…20 mA – – – 4…20 mA – – – Potential isolation Per module – – – Fieldbus connection Suitable communication interface module CI501-PNIO, CI502-PNIO, CI504-PNIO, CI506-PNIO, CI541-DP, CI542-DP, CI581-CN, CI582-CN, DC551-CS31, CI592-CS31 3

3/46 | ABB PLC Automation AC500-eCo Technical data FM562 positioning module The FM562 module contains Pulse Train Outputs for 2 axes. Profile generator for simple motion control tasks are integrated. The RS422 outputs allow a direct connection to Stepper- or Servo drives. Function blocks in PLCopen ® motion control style allow the integration of the module in an application. These function blocks are contained in the library PS552-MC-E. Type FM562 Functionality Number of axis 2 Digital inputs 2 digital inputs per axis Function: for axis enable or limit switch Pulse outputs Modes cw/ccw or pulse/direction Built in profile generators Data of the digital inputs Signal voltage 24 V DC Input current at 24 V DC typically 5 mA Potential isolation by groups of 2 Data of pulse outputs Signal RS422 (differential) Frequency range 0...250 kHz Potential isolation RS422 outputs of both axis in one group isolated against the inputs, the process voltage and the PLC CPU logic Maximum cable length for digital inputs Cable shielded 500 m unshielded 300 m Maximum cable length for pulse outputs Cable shielded 300 m unshielded 30 m Process voltage UP Nominal voltage 24 V DC Current consumption on UP typically 0.04 A Reverse polarity protection Potential isolation Per module Voltage supply for the internal logic From UP / ZP with isolation Fieldbus connection Suitable communication interface module CI501-PNIO, CI502-PNIO, CI504-PNIO, CI506-PNIO, CI541-DP, CI542-DP 3

ABB PLC Automation | 3/47 AC500-eCo System data Environmental conditions Process and supply voltages 24 V DC Process and supply voltage 24 V DC (-15 %, +20 % without ripple) Absolute limits 19.2...30 V inclusive ripple Ripple 5 % Protection against reverse polarity 10 s 120 V AC Line voltage 120 V AC (-15 %, +10 %) Frequency 47...62.4 Hz / 50...60 Hz (-6 %, +4 %) 230 V AC Line voltage 230 V AC (-15 %, +10 %) Frequency 47...62.4 Hz / 50...60 Hz (-6 %, +4 %) 120–240 V AC Wide-range supplyLine voltage 102...264 V / 120..240 V (-15 %, +10 %) Frequency 47...62.4 Hz / 50...60 Hz (-6 %, +4 %) Allowed interruptions of power supply DC supply Interruption 10 ms, time between 2 interruptions 1 s, PS2 AC supply Interruption 0.5 periods, time between 2 interruptions 1 s Important: Exceeding the maximum power supply voltage ( 30 V DC) for process or supply voltages could lead to unrecoverable damage of the system. The system could be destroyed. The creepage distances and clearances meet the requirements of the overvoltage category II, pollution degree 2. For the supply of the modules, power supply units according to PELV specifications must be used. Climatic conditions Temperature Operation 0...60 °C (horizontal mounting of modules)0...40 °C (vertical mounting of modules and output load reduced to 50 % per group) Storage -40...+70 °C Transport -40...+70 °C Humidity Without condensation Max. 95 % Air pressure Operation 800 hPa / 2000 m Storage 660 hPa / 3500 m Electromagnetic Compatibility Radiated emission (radio disturbances) Acc. to IEC61000-6-4 Conducted emission (radio disturbances) Acc. to IEC61000-6-4 Electrostatic discharge (ESD) Acc. to EN 61000-4-2, zone B, criterion B Fast transient interference voltages (burst) Acc. to EN 61000-4-4, zone B, criterion B High energy transient interference voltages (surge) Acc. to EN 61000-4-5, zone B, criterion B Influence of radiated disturbances Acc. to IEC 61000-4-3, zone B, criterion A Influence of line-conducted interferences Acc. to IEC 61000-4-6, zone B, criterion A In order to prevent operating malfunctions, it is recommended, that the operating personnel discharge themselves prior to touching communication connectors or perform other suitable measures to reduce effects of electrostatic discharges. The connector of the I/O-Bus must not be touched during operation. Mechanical data Wiring method Available types of terminal Spring terminals, screw terminals Degree of protection IP 20 (if all terminal screws are tightened) Vibration resistance Acc. to IEC 61131-2 Shock resistance Acc. to IEC 60068-2-27 Assembly position Horizontal no derating Vertical max. ambient temp. 40°C and output load reduced to 50% per group Assembly on DIN rail Acc. to IEC 60715 DIN rail type 35 mm, depth 7.5 mm or 15 mm Assembly with screws Screw diameter 4 mm Fastening torque 1.2 Nm Main dimensions mm, inches 135 5.31” 75 2.96” 82 3.23” 135 5.31” 75 2.96” 34 1.34” 3

3/48 | ABB PLC Automation AC500-eCo System data Environmental tests Climatic and mechanical tests Storage Cold withstand test IEC 60068-2-1 Test Ab: cold withstand test -40 °C / 16 h Dry heat withstand test IEC 60068-2-2 Test Bb: dry heat withstand test +70 °C / 16 h Humidity Damp heat test IEC 60068-2-30 Test Db: Cyclic (12 h / 12 h) Damp-Heat Test 55 °C, 93 % r. H. / 25 °C, 95 % r. H., 2 cycles Insulation Test Acc. to IEC 61131-2 Vibration resistance DIN rail mounting all three axes 5...11.9 Hz, continuous 3.5 mm 11.9…150 Hz, continuous 1 g With SD Memory Card inserted 15…150 Hz, continuous 1 g Shock resistance DIN rail mounting IEC 60068-2-27: all 3 axes 15 g, 11 ms, half-sinusoidal EMC immunity tests Electrostatic discharge (ESD) Electrostatic voltage in case of air discharge 8 kV Electrostatic voltage in case of contact discharge 6 kV Fast transient interference voltages (burst) Supply voltage units (AC, DC) 2 kV Digital inputs/outputs (24 V DC) 2 kV Digital inputs/outputs (120/230 V AC) 2 kV Analog inputs/outputs 1 kV CS31 system bus 2 kV Serial RS-485 interfaces (COM) 2 kV Ethernet 1 kV I/O supply, DC-out 1 kV High energy transient interference voltages (surge) Power supply AC 2 kV CM (1) / 1 kV DM (2) Power supply DC 1 kV CM (1) / 0.5 kV DM (2) DC I/O supply, add. DC-supply-out 0.5 kV CM (1) / 0.5 kV DM (2) Buses, shielded 1 kV CM (1) AC-I/O unshielded 2 kV CM (1) / 1 kV DM (2) I/O analog, I/O DC unshielded 1 kV CM (1) / 0.5 kV DM (2) Influence of radiated disturbances Test field strength 10 V/m Influence of line-conducted interferences Test voltage 3V zone B, 10 V is also met. (1) CM = Common Mode.(2) DM = Differential Mode. 3

ABB PLC Automation | 3/49 3

4/50 | ABB PLC Automation 4

ABB PLC Automation | 4/51 AC500 High performance modular PLC Key features 4/52 Ordering data 4/53 Technical data 4/60 System data 4/84 4

4/52 | ABB PLC Automation AC500 Key features Common AC500 platform benefits: Automation Builder engineering suite, I/O modules, scalable and flexible A high performance PLC:– Highly modular– From 8 to +80 000 I/Os– More communication possibilities (Ethernet, Internet, PROFINET ® , PROFIBUS ® , Modbus ® , CANopen ® , EtherCAT ® …) – Eight programming languages available (five IEC61131-3, CFC, C-code and C++) – Data logging– SD card for program back-up– High Availability (HA) option– Screw or spring terminal for I/Os– Extensive programming libraries 4

ABB PLC Automation | 4/53 AC500 CPUs – 2 internal serial interfaces, RS232 / RS485 configurable – Display and 8 function keys for diagnosis and status – Centrally expandable with up to 10 I/O modules, 320 I/Os (S500 and/or S500-eCo modules allowed) – Simultaneous operation of up to 4 external communication modules in any desired combination – Optional SD card for data storage and program backup – Can also be used as slave on PROFIBUS ® DP, DeviceNet or CANopen ® via FieldBusPlug, CANopen ® also using CM588 slave communication module – Ethernet version provides web server and IEC 60870-5-104 remote control protocol. Program memory Cycle time in µs per instruction min. Integrated communication Type Order code Price Weight(1 pce) kB Bit/Word/Float. point kg 128 0.06 / 0.09 / 0.7 2 x serial PM572 1SAP130200R0200 0.135 512 0.06 / 0.09 / 0.7 Ethernet (2), 2 x serial PM573-ETH (1) 1SAP130300R0271 0.150 512 0.05 / 0.06 / 0.5 2 x serial PM582 1SAP140200R0201 0.135 1024 0.05 / 0.06 / 0.5 Ethernet (2), 2 x serial PM583-ETH (1) 1SAP140300R0271 0.150 1024 0.004 / 0.008 / 0.008 Ethernet (2), 2 x serial PM585-ETH (1) 1SAP140500R0271 0.150 2048 0.002 / 0.004 / 0.004 Ethernet (2), 2 x serial PM590-ETH (1) 1SAP150000R0271 0.150 4096 0.002 / 0.004 / 0.004 Ethernet (2), 2 x serial PM591-ETH (1) 1SAP150100R0271 0.150 4096 0.002 / 0.004 / 0.004 2 x Ethernet (2), 1 x serial PM591-2ETH (1)(5) 1SAP150100R0277 0.150 4096 0.002 / 0.004 / 0.004 Ethernet (2), 2 x serial PM592-ETH (1)(3) 1SAP150200R0271 0.150 PM572 PM592 AC500 Ordering data AC500 CPU PM595 – 2 Ethernet interfaces with integrated switch and software configurable protocol (PROFINET, EtherCAT (4)) – 2 independent Ethernet interfaces – 2 serial interfaces, RS232 / RS485 configurable – Provides web server and IEC 60870-5-104 telecontrol protocol – Centrally expandable with up to 10 I/O modules (S500 and/or S500-eCo modules allowed) – Simultaneous operation of up to 2 external communication modules in any desired combination Program memory Cycle time in µs per instruction min. Integrated communication Type Order code Price Weight(1 pce) MB Bit/Word/Float. point kg 16 0.0006/0.001/0.001 2 x Ethernet (2 Ports switch), 2 x Ethernet (2), 2 x serial PM595-4ETH-F (3) 1SAP155500R0279 1.050 (1) Ethernet communication.(2) Provides integrated web server and IEC 60870-5-104 remote control protocol on each interface independently.(3) Provides integrated 4 GB flashdisk for user data storage and data logging.(4) Availability on demand.(5) Only to be used with dedicated terminal base TB523-2ETH. PM595-4ETH-F AC500 Machine controller kits – Complete product bundle providing all the needed devices for a machine controller delivered under one single order code. Program memory Cycle time in µs per instruction min. Contents / Integrated communication Type Order code Price Weight(1 pce) kB Bit/Word/Float. point kg 1024 0.004 / 0.008 / 0.008 PM585-ETH, CM579-ETHCAT, TB511-ETH Ethernet (2), 2 x serial, EtherCAT Master PM585-MC-KIT 1SAP140500R0379 0.500 2048 0.002 / 0.004 / 0.004 PM590-ETH, CM579-ETHCAT, TB521-ETH, TA524 Ethernet (2), 2 x serial, EtherCAT Master PM590-MC-KIT 1SAP150000R0379 0.500 PM585-MC-KIT 4

4/54 | ABB PLC Automation AC500 Ordering data Terminal base – For mounting and connection of the CPUs and communication modules, not needed for PM595 – 1 to 4 plug-in communication modules – Connection for communication coupler integrated in the CPU – I/O interface for direct connection of up to 10 expansion modules – Fieldbus-neutral FieldBusPlug-Slave interface not for TB523-2ETH – Connection COM1: 9-pole pluggable terminal block – Connection COM2: 9-pole Sub-D (not for TB523-2ETH). Number of coupler slots Connection for coupler integrated in the CPU Type Order code Price Weight(1 pce) kg 1 Ethernet RJ45 TB511-ETH 1SAP111100R0270 0.215 2 Ethernet RJ45 TB521-ETH 1SAP112100R0270 0.215 2 2x Ethernet RJ45 TB523-2ETH (1) 1SAP112300R0277 0.250 4 Ethernet RJ45 TB541-ETH 1SAP114100R0270 0.215 Note: These TBs are compatible with previous AC500 CPU versions (R01xx) and new ones (R02xx).(1) Can only be used together the PM591-2ETH. TB511-ETH TB541-ETH AC500 Condition Monitoring CMS – PLC integrated condition monitoring and fast protection for high frequency signals (vibration, current , voltage, speed/encoder) – FM502-CMS module needs function module terminal base TF5x1 for direct interfacing to CPU, communication couplers, other I/O – for stand-alone or control/safety integrated condition monitoring – PM592 CPU to be used on same TF5x1 for data storage and signal processing or communication – C-code interface for own complex diagnosis algorithmns, 4GB Flash disk for raw fingerprints and indicator trending – FM502-CMS module: – 16 fast, precise analog inputs, all synchronously sampled; configurable as IEPE or +-10V – individual measurement configuration (start,stop,trigger) per channel – per channel up to 50ksamples/s and 24bit ADC resolution, adjustable sampling – encoder inputs (5V or 24V) up to 300kHz counter; 12 modes, incl. absloute SSI (1MHz) – fast data logging, compact WAV-Files delivered automatically to CPU, incl. synchronized encoder signal if configured – analogue values always available for fast protection in I/O image of CPU – Included in Automation Builder: Configuration, libraries for CMS control and wav file handling, examples – Available download package: Signal processing library, example programs with simple diagnosis, logging and automated triggering (2) Number of coupler slots Description Type Order code Price Weight(1 pce) kg n.a. Function Module for Condition Monitoring Systems, 16AI, 2DI, 2DC, 1x Encoder (A, B, Z) FM502-CMS (3) 1SAP260400R0001 0.215 0 Function module terminal base for FM502, no coupler slots, 1x ETHERNET, 1x serial, spring terminals, 24VDC TF501-CMS (1)(3) 1SAP117000R0271 0.350 2 Function module terminal base for FM502, 2x coupler slots, 1x ETHERNET, 1x serial, spring terminals, 24VDC TF521-CMS (1)(3) 1SAP117200R0271 0.400 (1) Can only be used together with FM502 and PM592-ETH(2) Download of Package under "Application Examples" at www.abb.com/plc(3) Availability planned for Q1/2016. FM502-CMS TF501-CMS TF521-CMS 4

ABB PLC Automation | 4/55 AC500 Ordering data CM592-DP I/O modules – For central expansion of the AC500 or AC500-eCo CPUs – For decentralized expansion in combination with communication interface modules on CS31, PROFINET ® IO, PROFIBUS ® DP, CANopen ® modules – DC: Channels can be configured individually as inputs or outputs – Plug-in electronic modules, terminal unit required (refer to table below). Digital I/O Number of Input signal Output type Output signal Terminal units Screw / Spring Type Order code Price Weight(1 pce) DI/DO/DC kg 32 / – / – 24 V DC – – TU515 / TU516 DI524 1SAP240000R0001 0.200 – / – / 16 24 V DC Transistor 24 V DC, 0.5 A TU515 / TU516 DC522 1SAP240600R0001 0.200 – / – / 24 24 V DC Transistor 24 V DC, 0.5 A TU515 / TU516 DC523 1SAP240500R0001 0.200 16 / – / 16 24 V DC Transistor 24 V DC, 0.5 A TU515 / TU516 DC532 1SAP240100R0001 0.200 8 / 8 / – 24 V DC Relay 230 V AC, 3 A (1) TU531 / TU532 DX522 1SAP245200R0001 0.300 8 / 4 / – 230 V AC Relay 230 V AC, 3 A (1) TU531 / TU532 DX531 1SAP245000R0001 0.300 – / 32 / – 24 V DC Transistor 24 V DC, 0.5 A TU515 / TU516 DO524 1SAP240700R0001 0.200 (1) Relay outputs, changeover contacts.. Communication modules Protocol Connections Type Order code Price Weight(1 pce) kg PROFIBUS ® DP V0/V1 master Sub-D socket 9 poles CM592-DP (1) 1SAP173200R0001 0.115 Ethernet (TCP/IP, UDP/IP, Modbus ® TCP) 2 x RJ45 - integrated switch CM597-ETH 1SAP173700R0001 0.115 CANopen ® master Terminal block 2 x 5 poles spring CM598-CN (1) 1SAP173800R0001 0.115 CANopen ® slave Terminal block 2 x 5 poles spring CM588-CN 1SAP172800R0001 0.115 PROFINET ® I/O RT controller 2 x RJ45 - integrated switch CM579-PNIO 1SAP170901R0101 0.115 PROFINET ® IO RT device 2xRJ45 - integrated switch CM589-PNIO 1SAP172900R0011 0.115 EtherCAT ® master 2 x RJ45 CM579-ETHCAT (1) 1SAP170902R0101 0.115 Serial + co-processor 2 x RS-232/485 on spring terminal blocks CM574-RS 1SAP170400R0201 0.115 Serial RCOM 2 x RS-232/485 (1 x RCOM/1 x Console) CM574-RCOM 1SAP170401R0201 0.115 (1) Availability planned for Q1/2016 DO524 CM574-RSCM574-RCOM CM598-CN CM579-PNIO 4

4/56 | ABB PLC Automation AC500 Ordering data Analog I/O Number of Input signal Output signal Terminal units Screw / Spring Type Order code Price Weight(1 pce) AI/AO kg 16 / 0 0...10 V, ±10 V 0/4...20 mA, PT100, PT1000, Ni1000 – TU515 / TU516 AI523 1SAP250300R0001 0.200 4 / 4 ±10 V 0/4...20 mA TU515 / TU516 AX521 1SAP250100R0001 0.200 8 / 8 (max. 4 current outputs) TU515 / TU516 AX522 1SAP250000R0001 0.200 0 / 16 (max. 8 current outputs) – TU515 / TU516 AO523 1SAP250200R0001 0.200 8 / 0 0…5 V, 0…10 V, ±50 mV, ±500 mV, 1 V, ±5 V, ±10 V, 0/4…20 mA, ±20 mA, PT100, PT1000, Ni1000, Cu50, 0…50 kΩ, S, T, N, K, J – TU515 / TU516 AI531 1SAP250600R0001 0.200 Analog/digital mixed I/O Standard I/O module with high functionality: – 16 digital input or 16 digital output channels – 8 configurable In/Output channels – first two inputs are also usable as high-speed counter (up to 50 kHz) together with AC500 CPU, CS31 or CI5xx communication interface modules. – 4 independent analog input channels configurable for voltage, current, 12 bit + sign, 1-2 wire connection – Galvanic isolation per module – Compatible with all CI5xx modules. Number of Input signal Output type Output signal Terminal unit Screw / Spring Type Order code Price Weight(1 pce) AI/AO/DI/DO/DC kg 4 / 2 / 16 / - / 8 24 V DC/0…10 V, -10…+10 V, 0…20 mA, 4…20 mA, PT100, PT1000, Ni100, Ni1000 Transistor 24 V DC, 0.5 A/ -10…+10 V, 0…20 mA, 4…20 mA TU515 / TU516 DA501 1SAP250700R0001 0.200 4 / 2 / - / 16 / 8 24 V DC/0…10 V, -10…+10 V, 0…20 mA, 4…20 mA, PT100, PT1000, Ni100, Ni1000 Transistor 24 V DC, 0.5 A/ -10…+10 V, 0…20 mA, 4…20 mA TU515 / TU516 DA502 1SAP250800R0001 0.200 DA501 Multifunctional modules Functionality Number of Input signal Output type Output signal Terminal units Screw / Spring Type Order code Price Weight(1 pce) DI/DO/DC kg Encoder module Encoder and PWM module 2 / – / 8 24 V DC and 2 encoder inputs A/B/C differential 2 PWM outputs 24 V DC, 0.1 A TU515 / TU516 CD522 1SAP260300R0001 0.125 – DC541 occupies one communication module slot on the AC500 CPU terminal base, no terminal block required – Usable with all CI5xx modules. Functionality Number of Input signal Output type Output signal Terminal unit Type Order code Price Weight(1 pce) DI/DO/DC kg Interrupt I/O and fast counter module Interrupt I/O and fast counter – / – / 8 24 V DC Transistor 24 V DC, 0.5 A N/A (2) DC541-CM (1) 1SAP270000R0001 0.100 (1) Multifunctional module, refer to table on page 69 for details.(2) Occupies a communication module slot. AO523 CD522 DA502 4

ABB PLC Automation | 4/57 AC500 Ordering data From To Output signal Terminal units Type Order code Price Weight(1 pce) kg Gateway on Ethernet based protocol - PROFINET ® IO RT PROFINET ® I/O – 3 x RS232/485 ASCII serial interfaces TU520-ETH CI504-PNIO 1SAP221300R0001 0.200 PROFINET ® I/O 1x CAN 2A/2B or CANopen ® Master 2 x RS232/485 ASCII serial interfaces TU520-ETH CI506-PNIO 1SAP221500R0001 0.200 Communication interface modules Number of Input signal Output type Output signal Terminal units Screw / Spring Type Order code Price Weight(1 pce) AI/AO/DI/DO/DC kg For CS31-Bus - / - / 8 / - / 16 24 V DC Transistor 24 V DC, 0.5 A TU551-CS31 / TU552-CS31 DC551-CS31 1SAP220500R0001 0.200 - / - / - / - / 16 24 V DC Transistor 24 V DC, 0.5 A TU551-CS31 / TU552-CS31 CI590-CS31-HA 1SAP221100R0001 0.200 4 / 2 / 8 / - / 8 24 V DC/ 0…10 V, -10…+10 V, 0…20 mA, 4…20 mA, PT100, PT1000, Ni100, Ni1000 Transistor 24 V DC, 0.5 A/ -10…+10 V, 0…20 mA, 4…20 mA TU551-CS31 / TU552-CS31 CI592-CS31 1SAP221200R0001 0.200 For PROFIBUS ® -DP 4 / 2 / 8 / 8 / - 24 V DC/ 0…10 V, -10…+10 V, 0…20 mA, 4…20 mA, PT100, PT1000, Ni100, Ni1000 Transistor 24 V DC, 0.5 A/ -10…+10 V, 0…20 mA, 4…20 mA (1) TU509/TU510/ TU517/TU518 CI541-DP 1SAP224100R0001 0.200 - / - / 8 / 8 / 8 24 V DC Transistor 24 V DC, 0.5 A TU509/TU510/ TU517/TU518 CI542-DP 1SAP224200R0001 0.200 For CANopen ® 4 / 2 / 8 / 8 / - 24 V DC/ 0…10 V, -10…+10 V, 0…20 mA, 4…20 mA, PT100, PT1000, Ni100, Ni1000 Transistor 24 V DC, 0.5 A/ -10…+10 V, 0…20 mA, 4…20 mA TU509/TU510/ TU517/TU518 CI581-CN 1SAP228100R0001 0.200 - / - / 8 / 8 / 8 24 V DC Transistor 24 V DC, 0.5 A TU509/TU510/ TU517/TU518 CI582-CN 1SAP228200R0001 0.200 For Ethernet based protocol - EtherCAT ® 4 / 2 / 8 / 8 / - 24 V DC/0…10 V, -10…+10 V, 0…20 mA, 4…20 mA, PT100, PT1000, Ni100, Ni1000 Transistor 24 V DC, 0.5 A / -10…+10 V, 0…20 mA, 4…20 mA TU507-ETH / TU508-ETH CI511-ETHCAT 1SAP220900R0001 0.200 - / - / 8 / 8 / 8 24 V DC Transistor 24 V DC, 0.5 A TU507-ETH / TU508-ETH CI512-ETHCAT 1SAP221000R0001 0.200 For Ethernet based protocol - PROFINET ® IO RT 4/2/8/8/- 24 V DC/0…10 V, -10…+10 V, 0…20 mA, 4…20 mA, PT100, PT1000, Ni100, Ni1000 Transistor 24 V DC, 0.5 A/ -10…+10 V, 0…20 mA, 4…20 mA TU507-ETH / TU508-ETH CI501-PNIO 1SAP220600R0001 0.200 -/-/8/8/8 24 V DC Transistor 24 V DC, 0.5 A TU507-ETH / TU508-ETH CI502-PNIO 1SAP220700R0001 0.200 CI581-CN CI511-ETHCAT CI501-PNIO CI504-PNIO CI541-DP 4

4/58 | ABB PLC Automation AC500 Ordering data Terminal units For digital and analog expansion modules and interface modules. Please note: for modules with relay outputs, terminal units for 230 V AC (TU531 / TU532) are required. For Supply Connection type Type Order code Price Weight(1 pce) kg Ethernet communication interface modules 24 V DC Screw TU507-ETH 1SAP214200R0001 0.300 Spring TU508-ETH 1SAP214000R0001 0.300 Ethernet gateway modules 24 V DC Spring TU520-ETH 1SAP214400R0001 0.300 CANopen ® / PROFIBUS ® DP (1) communication interface modules 24 V DC Screw TU517 1SAP211400R0001 0.300 Spring TU518 1SAP211200R0001 0.300 PROFIBUS ® DP / CANopen ® communication interface modules 24 V DC Screw TU509 1SAP211000R0001 0.300 Spring TU510 1SAP210800R0001 0.300 I/O modules 24 V DC Screw TU515 1SAP212200R0001 0.300 Spring TU516 1SAP212000R0001 0.300 I/O modules AC / relay 230 V AC Screw TU531 1SAP217200R0001 0.300 Spring TU532 1SAP217000R0001 0.300 CS31 interface modules 24 V DC Screw TU551-CS31 1SAP210600R0001 0.300 Spring TU552-CS31 1SAP210400R0001 0.300 (1) TU517/TU518 Terminal units can also be used with PROFIBUS ® DP CI54x modules up to 1 Mbaud. TU515 TU520-ETH TU510 TU518 Terminal units compatibility Type For I/O modules For communication interface modules TU515 TU516 TU531 TU532 TU507-ETH TU508-ETH TU509 TU510 TU517 TU518 TU520-ETH TU551-CS31 TU552-CS31 DA501 DA502 DC522 DC523 DC532 DI524 DX522 DX531 DO524 CD522 AI523 AI531 AO523 AX521 AX522 DC551-CS31 CI590-CS31-HA CI592-CS31 CI501-PNIO CI502-PNIO CI504-PNIO CI506-PNIO CI511-ETHCAT CI512-ETHCAT CI541-DP (1) CI542-DP (1) CI581-CN CI582-CN (1) Can be used with baud rate up to 1 Mbaud. TU508-ETH 4

ABB PLC Automation | 4/59 AC500 Ordering data Accessories for AC500 For Description Type Order code Price Weight(1 pce) kg AC500 CPUs COM1 Programming cable Sub-D / terminal block, length 5 m TK502 1SAP180200R0101 0.400 AC500 CPUs COM2 Programming cable Sub-D / Sub-D, length 5 m TK501 1SAP180200R0001 0.400 AC500 CPUs Memory card (2 GB SD card) MC502 1SAP180100R0001 0.020 Lithium battery for data buffering TA521 1SAP180300R0001 0.100 I/O modules Pluggable marker holder for I/O modules, packing unit incl. 10 pcs. Template available in the AC500 online help TA523 1SAP180500R0001 0.300 AC500 CPU´s, interface module, communication module and I/O modules White labels, packaging unit incl.10 pcs. TA525 1SAP180700R0001 0.100 Terminal base Communication Module, blind cap TA524 1SAP180600R0001 0.120 CPU terminal base Accessories for wall mounting, packing unit includes 10 pcs TA526 1SAP180800R0001 0.200 5-pole power plug for AC500. Spare part. Can be plugged to CPU terminal base TB5x1. Packing unit includes 5 pcs TA527 1SAP181100R0001 0.200 9-pole COM1 plug for AC500. Spare part. Can be plugged to CPU terminal base TB5x1. Packing unit includes 5 pcs TA528 1SAP181200R0001 0.200 Communication modules 9-pole spring plug for CM574-RS/RCOM. Spare part. Packing includes 10 pcs TA532 1SAP182000R0001 5-pole spring plug for CM575-DN/CM578-CN. Spare part. Packing includes 5 pcs TA533 1SAP182100R0001 2x5-pole spring plug for CM588-CN. Spare part. Packing includes 5 pcs. TA534 1SAP182200R0001 10-pole spring plug for DC541-CM. Spare part. Packing includes 10 pcs. TA536 1SAP183100R0001 AC500 basic training case CPU, I/Os, HMI PM583-ETH + MC502 + CM572-DP + AX561 + DC551-CS31 + CI542-DP + CP635 + power supply + Ethernet cables + simulation stand TA512-BAS 1SAP182400R0001 7.000 AC500 advanced training case CPU, I/Os, COM, encoder PM583-ETH + CM502 + CM574-RS + CM578-CN + CM579-PNIO + CM579-ETHCAT + CI512-ETHCAT + CP635 + CD522 + power supply + cables + simulation stand TA513-ADV 1SAP182500R0001 8.800 AC500 CPUs PM595 Protective cap, spare-parts, 3 pieces TA540 1SAP182600R0001 0.200 Lithium battery for real-time-clock buffering TA541 1SAP182700R0001 0.030 Accessories for screw-mounting, 20 pieces TA543 1SAP182800R0001 0.100 MC502 AC500 basic training caseCPU, I/Os, HMI 4