Carrinho de compras

Ficha técnica de produto | CoreSense da ABB (EN)

Consulte as caraterísticas técnicas de produto

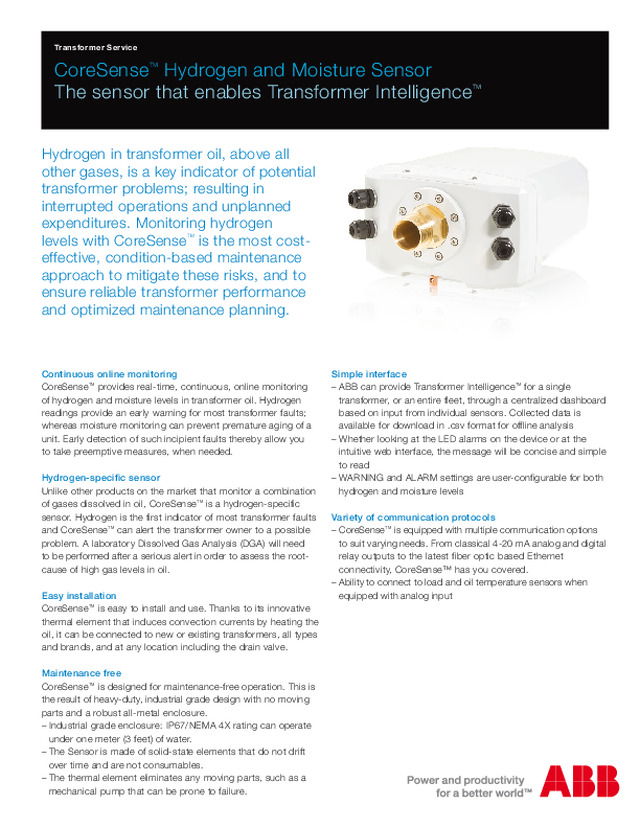

CoreSense TM Hydrogen and Moisture Sensor The sensor that enables Transformer Intelligence TM Transformer Service Continuous online monitoring CoreSense TM provides real-time, continuous, online monitoring of hydrogen and moisture levels in transformer oil. Hydrogen readings provide an early warning for most transformer faults; whereas moisture monitoring can prevent premature aging of a unit. Early detection of such incipient faults thereby allow you to take preemptive measures, when needed. Hydrogen-specific sensor Unlike other products on the market that monitor a combination of gases dissolved in oil, CoreSense TM is a hydrogen-specific sensor. Hydrogen is the first indicator of most transformer faults and CoreSense TM can alert the transformer owner to a possible problem. A laboratory Dissolved Gas Analysis (DGA) will need to be performed after a serious alert in order to assess the root-cause of high gas levels in oil. Easy installation CoreSense TM is easy to install and use. Thanks to its innovative thermal element that induces convection currents by heating the oil, it can be connected to new or existing transformers, all types and brands, and at any location including the drain valve. Maintenance free CoreSense TM is designed for maintenance-free operation. This is the result of heavy-duty, industrial grade design with no moving parts and a robust all-metal enclosure.– Industrial grade enclosure: IP67/NEMA 4X rating can operate under one meter (3 feet) of water.– The Sensor is made of solid-state elements that do not drift over time and are not consumables.– The thermal element eliminates any moving parts, such as a mechanical pump that can be prone to failure. Simple interface – ABB can provide Transformer Intelligence TM for a single transformer, or an entire fleet, through a centralized dashboard based on input from individual sensors. Collected data is available for download in .csv format for offline analysis – Whether looking at the LED alarms on the device or at the intuitive web interface, the message will be concise and simple to read– WARNING and ALARM settings are user-configurable for both hydrogen and moisture levels Variety of communication protocols – CoreSense TM is equipped with multiple communication options to suit varying needs. From classical 4-20 mA analog and digital relay outputs to the latest fiber optic based Ethernet connectivity, CoreSense™ has you covered.– Ability to connect to load and oil temperature sensors when equipped with analog input Hydrogen in transformer oil, above all other gases, is a key indicator of potential transformer problems; resulting in interrupted operations and unplanned expenditures. Monitoring hydrogen levels with CoreSense TM is the most cost- effective, condition-based maintenance approach to mitigate these risks, and to ensure reliable transformer performance and optimized maintenance planning.

ENG /August 2015 Moisture (CoreSense 2 only) Moisture measurement range 0 to 1 aw Moisture measurement accuracy ± 0.02 aw Temperature measurement accuracy ± 0.2 °C Mechanical specifications Dimensions 392 x 264 x 158 mm (14.43 x 10.39 x 6.2 in) Weight 8 kg (18 lbs) Interface to transformer 1.5 NPT male thread Enclosure IP67\NEMA4X enclosure British Columbia104-1641 Commerce Avenue, Kelowna, BC V1X 8A9 www.abb.com/transformerservice Note: The information contained in this document is for general information purposes only. While ABB strives to keep the information up to date and correct, it makes no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the information, products, services, or related graphics contained in the document for any purpose. Any reliance placed on such information is therefore strictly at your own risk. ABB reserves the right to discontinue any product or service at any time. © Copyright 2015 ABB Inc. All rights reserved. For more information please contact: ABB Inc.Transformer Remanufacturing and Engineering Services (TRES) Customer Service Center1-800-HELP 365 (1-800-435-7365)[email protected] Quebec1600 Lionel-Boulet Boulevard, Varennes, QC J3X 1S4 Ontario201 Westcreek Boulevard, Brampton, ON L6T 5S6 Alberta9604 - 31 Avenue, Edmonton, AB T6N 1C4 Analogues interfaces Dry-contact relays for alarms 4–20 mA inputs 4–20 mA outputs (option) Environmental specifications Operating ambient temperature –50 °C to 55 °C / –58 °F to 131 °F Operating ambient humidity 5 to 95 % relative humidity, non-condensing Operating altitude –610 to 3,000 meters / -2000 to 9840 feet Oil temperature at valve –20 °C to 100 °C / –4 °F to 212 °F Oil pressure at valve 0 to 1000 kPA / 0 to 10 bar / 0 to 145 psi Electrical specifications Voltage input 100 to 240 VAC (50 to 60 Hz) Power consumption 150 VA Fuse type 1 x 1.0 A / 240 V (5 x 20 mm) slow blow (IEC60127 type T) Communications specifications LED Easy to read, three color code LED system indicates status of hydrogen and moisture levels Digital interfaces Modbus and DNP3 are available over the following interfaces: RS485 Ethernet Optical Ethernet (100BASE-FX) (option) Ready for IEC61850 Hydrogen Hydrogen measurement range 0 to 5,000 ppm with a limit of detection of 25 μl/l Hydrogen measurement accuracy ±25 ppm or ±20 % (whichever is higher) Measurement specifications